› Respiratory protection › Filters for Respiratory Masks › NATO 40x1/7 Thread Respirator Filters › Filter combined CleanAir MOF-6 thread 40x1/7

Filter combined CleanAir MOF-6 thread 40x1/7

Description

CLEANAIR MOF-6 GAS FILTER (A2B2E2K2-P3 D R)

The best materials and precise Czech production...

Technical Specifications:

- Connection: thread RD40×1/7"

- Colour marking: brown, grey, yellow, green and white stripe

- Certification: EN 14387, EN 12941, EN 12942

- diameter / height: 110 mm / 95 mm

- Weight: 400 g

- Art.No.: 50 01 68

The MOF-6 filter protects against:

organic gases and vapours with a boiling point above 65 °C, inorganic gases and vapours, acid gases and vapours, ammonia and organic amines, particulates.

- Hydrocarbons

e.g.: toluene, benzene, xylene, styrene, cyclohexane, trichloroethylene, carbon tetrachloride

- Organic solvents and thinners

e.g.: gasoline, kerosene, diesel, mineral turpentine, ethylene glycol, methyl isobutyl ketone, isobutanol, etc

- inorganic gases and vapours

e.g.: fluorine, chlorine, hydrogen sulphide, hydrogen cyanide, hydrogen bromide, hydrogen chloride or hydrogen peroxide.

- acid gases and vapours

e.g.: sulphur dioxide, sulphuric acid, hydrochloric acid, formic acid, hydrofluoric acid

- ammonia and organic amines

e.g.: methylamine, ethylamine, dimethylamine

- solid particles in the form of liquid and solid aerosols

e.g: dust, fibres, toxic and non-toxic fumes, bacteria, viruses, radioactive particles

- other captured substances are available in the detailed documentation

Filter lifetime

The lifetime of filters depends mainly on the concentration of pollutants in the workplace, humidity and air flow, i.e. the physical demands of working with the mask or the setting of the filter ventilation unit. Particulate filters Filters become clogged with particles and air moisture. If the breathing resistance increases during breathing, the filter should be changed immediately.

Restrictions on use

- When used against radioactive substances, bacteria and viruses, only single use is recommended!

- The filter cannot be used in environments with oxygen deficiency (<17%) or accidents (unknown pollutant concentration).

CleanAIR® filters

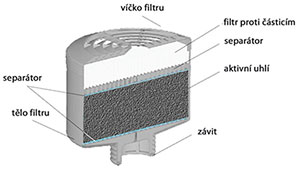

The body of the CleanAIR ® combined canister filter is made of highly durable plastic and the filter medium inside consists of two different parts: the activated carbon removes gaseous chemicals and vapours from the polluted air the P3 class filter medium removes solid and liquid particles from the contaminated air

The comprehensive CleanAIR® canister filter product range offers users a wide choice of filters for most industrial applications, pharmaceutical industry, laboratories and agriculture.

Principle of PARTS FILTRATION

The material used in the antiparticle filters is composed of layers of randomly stacked glass microfibres of various diameters from 1 to 10 μm.

The ability of an antiparticle filter to trap airborne pollutant particles is determined by the physical and mechanical properties of the filter media. The principle of filtration is based on the following mechanisms: INTERCEPTION, INERTIAL CONFINEMENT, DIFFUSION AND ELECTROSTATIC ATTRACTION

- INTERCEPTION (INTERCEPTION)

Small and light particles are able to pass along the filter fibres with the air flow. If the particle gets close to the filament (the distance between the centre of the particle and the filament is less than the diameter of the particle), it touches the filament and is captured. The larger the particle, the more efficient the capture.

- INERTIAL WEDGING

It is due to inertia. The heavier particles have a moment of inertia so great that they cannot follow the airflow around the filter fibres and continue in their original direction. This will cause them to impact and wedge on the fiber. Efficiency

inertial wedging increases with increasing air velocity, pollutant particle size and decreasing filter filament diameter.

- DIFUZE

Particles smaller than 1 μm also do not continue in the direction of airflow around the fibres. The essence of diffusion is that at the stated particle size of the pollutant, the so-called diffusion of the pollutant already occurs. Brownian motion (this is the random oscillatory motion of microscopic particles in a gas or liquid). During this oscillation, a contact with the fiber occurs, which traps the particle. The probability that a particle will be captured by diffusion increases with decreasing air velocity, decreasing particle size and decreasing filter fibre diameter.

- ELECTROSTATIC ATTRACTION

When the particle touches the fibre, the

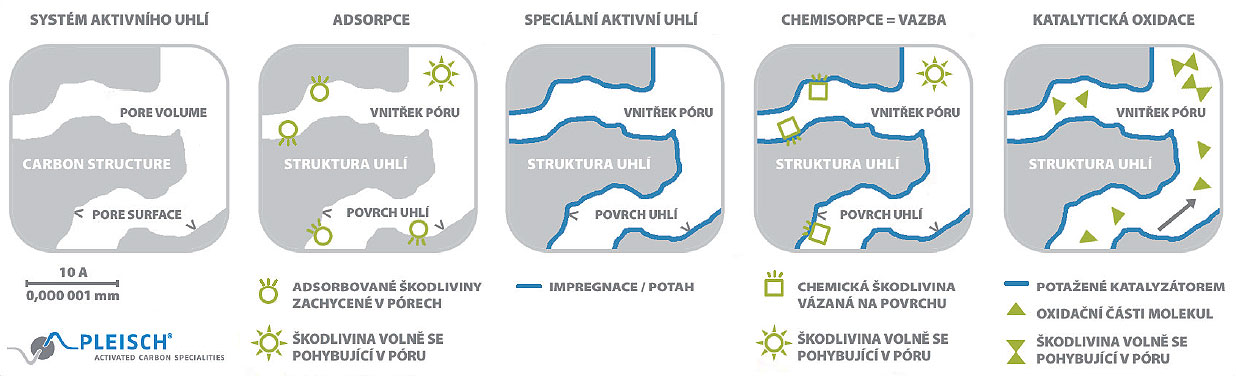

Gas Filtration - ACTIVE COAL

Carbon is activated by breaking down the structure of the carbon with hot steam or chemicals. This creates many tiny channels - micropores in the carbon structure. These pores are rough on the inside, allowing pollutant molecules to enter and bond with the surface. Depending on the degree of activation, the activated carbon has an internal active surface ranging from 750 m2/g to 1,600 m2/g.

Activated carbon can be in its basic raw form (for type A filters) or impregnated with various chemicals that give it, for example, oxidizing properties, acidic or basic properties. Pure activated carbon removes many aromatic substances from the air, including organic solvents and poisons - simple adsorption. However, some common gaseous chemicals (such as cyanide or ammonia) adsorb poorly or not at all. Therefore, in order to eliminate these poisons from the air, it is necessary to impregnate the activated carbon. For this purpose, the entire inner surface is coated with active substances (reactants) for these poisons, called chemisorption.

Activated carbon can be in its basic raw form (for type A filters) or impregnated with various chemicals that give it, for example, oxidizing properties, acidic or basic properties. Pure activated carbon removes many aromatic substances from the air, including organic solvents and poisons - simple adsorption. However, some common gaseous chemicals (such as cyanide or ammonia) adsorb poorly or not at all. Therefore, in order to eliminate these poisons from the air, it is necessary to impregnate the activated carbon. For this purpose, the entire inner surface is coated with active substances (reactants) for these poisons, called chemisorption.

Another group of chemicals needs to be removed using catalysts (e.g. organophosphines). In this case, the

the surface of the activated carbon is covered with these catalysts. The catalyst promotes the chemical reaction while making it

he stands alone unchanged. His only job is to facilitate the response.

The filters are supplied with standard connection thread RD40×1/7" according to EN 148-1 or OZ 40x4.

Related products

Be the first who will post an article to this item!